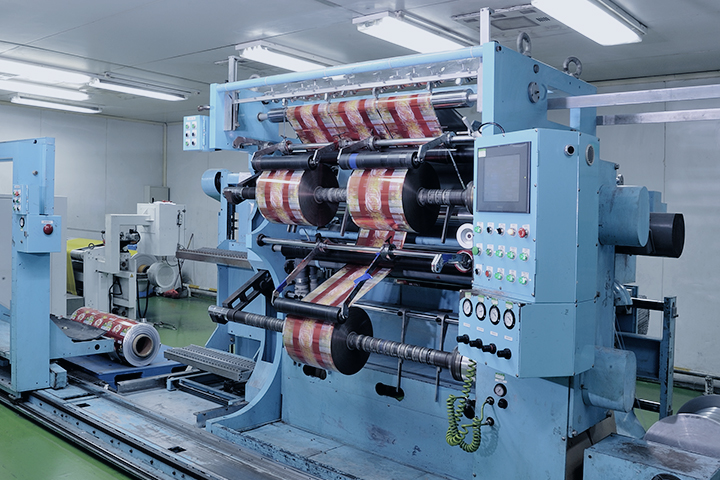

All Rotogravure printing machines are equipped with an advanced computerized-controlled color registration system and online display system. This can ensure excellent quality in every print under the low film tension condition to provide the high speed printing with different flexible and paper materials. Among the printing machines, there is a few which has an electronic axle print that has the capabilities of high printing speed up to 200 meters per minute.

-

Artwork design

-

Fuji 8-12 colors rotogravure printing

-

Overprint deviation ≤0.1mm

-

Onsite quality inspection

-

Reversed printing capability

-

Surface: matt, mirror, fluorescent anti-counterfeitin

-

Annual max. capacity 350 million meters